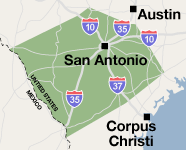

Commercial Concrete Leveling in San Antonio

Affordable permanent repairs for all sunken concrete problems

Watch to see how PolyLevel® can be used to level all types of commercial slabs.

Concrete is hard to beat as a basic material for all kinds of load-bearing surfaces, from driveways and sidewalks to floors, roads and airport runways. But concrete has two characteristics that can cause problems: It’s heavy and it can’t stretch.

The weight of a concrete slab can sometimes cause the soil beneath the slab to compress. When this happens, all or part of the concrete slab will sink down under its own weight, sometimes cracking in the process.

The cracking occurs because concrete isn’t a resilient material. If a slab is unevenly supported, it’s likely to crack because it can’t stretch or bend.

Foundation Supportworks, Inc. is San Antonio's expert concrete leveling contractor and PolyLevel® dealer. We can lift your sunken concrete slab using our fast, durable, cost-effective solution. Contact us today to schedule a consultation with one of our commercial technicians.

Concrete Lifting Repairs Restore Safety and Functionality

Instead of demolishing a sidewalk, roadway, or other concrete element that has settled, we can use different techniques for concrete leveling, while also strengthening and stabilizing the soil in the process.

Major highway repair without stopping traffic. Insulated hoses transport polyurethane resin and catalyst compounds to nozzles that mix the liquids and inject them beneath the settled slab. The rapidly expanding foam quickly permeates loose soil, fills voids, seals crevices and lifts the concrete –without any disruption of traffic. The polyurethane cures quickly after doing its slab-raising work, forming a permanent repair.

These proven concrete lifting techniques are more affordable and less disruptive than total replacement, and can be used in the following applications:

- Slab lifting for commercial/industrial buildings.This repair technique is sometimes referred to as “slab jacking.” It’s used on all types of sunken slabs in commercial and industrial buildings, including factory or warehouse floor slabs. By pumping a special mortar or an expanding foam beneath the slab, enough pressure is created to force the slab upwards. Once the mortar or polymer hardens, the repair is complete.

- Void-filling. Depending on the technique used, lifting settled or sunken concrete back to its original level can leave an airspace or void beneath the concrete. We often choose to fill this void with concrete or polymer material that can be pumped into the space. Void-filling techniques are also used to fill sinkholes, abandoned mines and open areas around well or tunnel casings.

- Concrete raising for roads, bridges, highways, railroads & runways. When these concrete elements sink, serious safety hazards occur, so repairs must be made right away. Foundation Supportworks, Inc. often relies on polymer injection or polyurethane concrete lifting to raise sunken concrete roads and runways. The main advantage with this technique is that the injected polymer cures to about 90% of its final strength within an hour after injection, enabling the road or runway to be used quickly.

- Pressure grouting with urethane. This technique is also referred to as “polymer injection.” It can be used for concrete lifting, as well as for void filling applications and for consolidating and strengthening soil prior to construction. The urethane polymer is activated during the application process, turning from a liquid into an expanding foam that flows into voids and pushes sunken concrete upwards.

- Sidewalk, stoop, & driveway lifting. Mudjacking and polymer injection are two concrete lifting techniques that geotechnical engineers use to repair sunken sidewalks, stoops, and driveways. Both techniques involve injecting material beneath the sunken element to create sufficient pressure for raising the sunken masonry.

- Rescuing a sinking in-ground pool. The combined weight of concrete and water can sometimes be too much for the underlying soil to bear. When this happens, an in-ground pool can begin to sink down. Foundation Supportworks, Inc. can solve this problem by injecting an expanding polymer compound beneath the pool. The polymer’s expanding force can raise up the sunken pool, while also improving the load-bearing qualities of the soil.

The PolyLevel® Concrete Lifting Product

Big lifting power through small holes. To lift a settled concrete slab with the PolyLevel® process, 5/8-in.-dia. holes are first drilled through the slab. After an injector port is screwed into each hole, a special nozzle mixes two reactive materials and sprays the expanding mixture beneath the slab.

The PolyLevel® System utilizes a high-strength polyurethane mixture to fill voids under concrete. With multiple formulas available, PolyLevel® is able to fit the needs of any job, large or small.

PolyLevel® is made up of a two-part urethane that expands into rigid foam that is used to fill voids, stabilize concrete, and lift concrete.

The PolyLevel® system has distinct advantages over other concrete remediation methods including: Light Weight - Material weighs approximately 4 pounds per cubic foot, which is significantly less than the 120 pounds per cubic foot of typical fill material.

Since PolyLevel® weighs as little as it does, there is almost no additional load added to the soil that is supporting the slab.

Advantages of the PolyLevel® Concrete Lifting Product:

- High Capacity - Lifting action is a result of the expansion of the foam allowing lift on much larger loads than typical mudjacking that relies on hydraulic pressure being contained under the slab.

- Accurate Lift - Reaction time of the foam allows for the most accurate lifts possible.

- Waterproof - Waterproof material will not wash out, and can be used to under-seal the slab or stop other infrastructure leaks.

- Non-Invasive - Equipment can be used in tight access areas, is less messy than other methods, and can be done more quickly.

- Quick Cure Time - Cure time allows for even heavy traffic just 15 minutes after completion of the injection of the material.

Polyurethane Concrete Lifting vs. Mud Jacking

Many concrete lifting techniques involve pumping either expanding foam (known as polymer, urethane, or polyurethane) or a Portland cement-based mortar beneath the settled concrete until enough pressure is created to lift the concrete back to its proper orientation.

Mud jacking or grout pumping is the older technique. Its main disadvantage is that the injected mortar must be allowed to cure before the repaired concrete can be used – a process that often takes several days.

Polyurethane lifting, on the other hand, has no such lag time, since the injected polyurethane foam typically expands and hardens to its final form within a matter of hours.

Learn more about our commercial foundation services or contact us now to request a consultation for your next commercial concrete leveling project.

Looking for a price? Get a no cost, no obligation free estimate.